Project Brief

John J Doyle Ltd was awarded a large contract by Dowds Group to complete the flue systems for a number of applications for the extension at Finnebrogue Artisan in Downpatrick.

Finnebrogue is the UK’s leading artisan food producer. The new plant-based food factory creates 300 new jobs in County Down, Northern Ireland.

Materials Used

Dinak DWJ Twin Wall 350Ø

Dinak DWJ Twin Wall 300Ø

Dinak DWJ Twin Wall 250Ø

Dinak DWJ Twin Wall 80Ø

SFL Twin Wall 350Ø

Result

Dowds Group awarded John J Doyle Ltd the contract to design, supply and install the flue systems for the Finnebrogue Artisan extension in Downpatrick. Each flue has to comply with different regulations set out within each application. This site required a number of systems including:

- 2 flue exhausts from Afrogrille Unit

- 2 flue exhausts from Easyfry Unit

- 1 flue from gas-fired boiler

- 1 flue from thermal oil boiler

- 1 flue from steam boiler

- 1 flue from IWM T400 conveyorised washer

- 1 flue from HC1000 cabinet washer

- 2 flues from ETW continuous bin washer

The project had very tight deadlines. John J Doyle Ltd was required to carry out surveys to order materials before the units and appliances were on site. John J Doyle Ltd keeps a variety of stock materials in our warehouse to allow us to adapt to changes onsite and respond to any emergencies.

AutoCAD drawings and calculations were carried out in-house to size the flue systems for each application and to ensure compliance with European standards and the Clean Air Act.

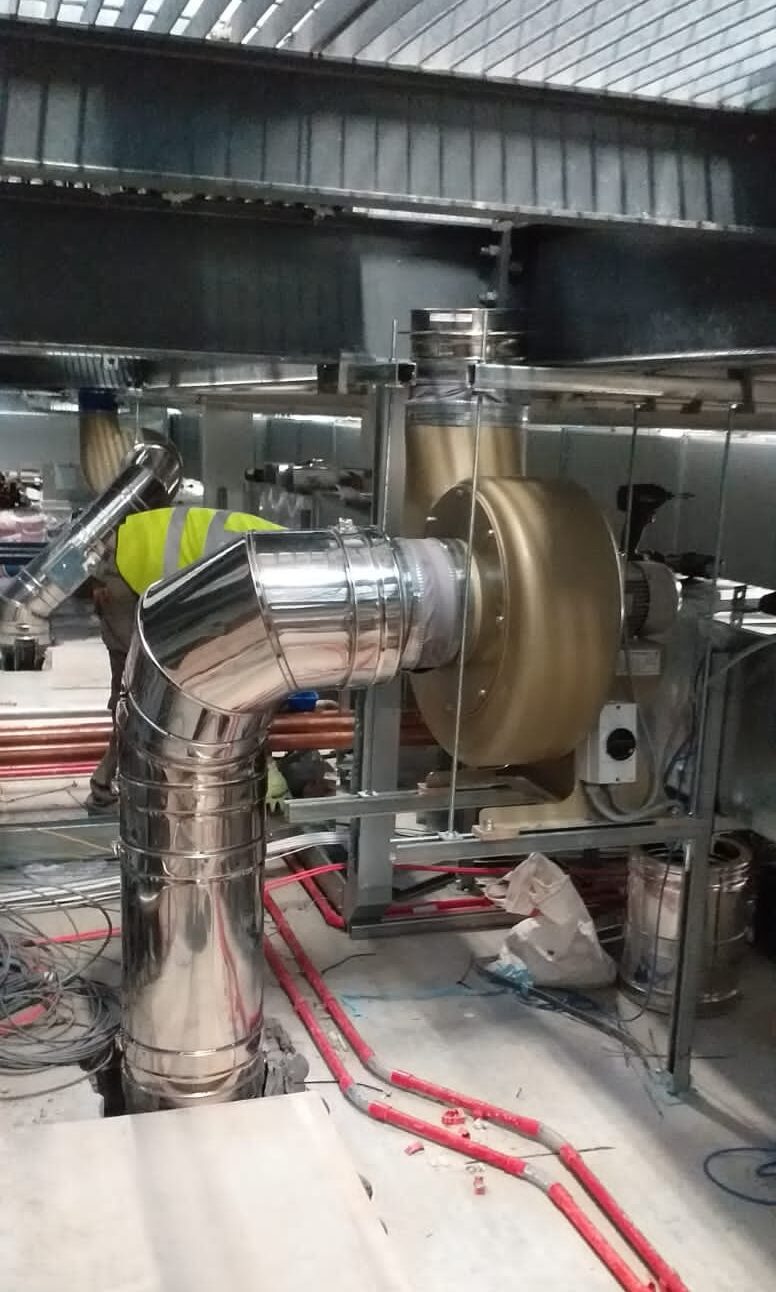

The Afrogrille and Easyfry units both required centrifugal fans installed within the roof space for the exhausts. Before and after each fan, fire suppression equipment had to be installed to specialised parts within the flue in order to met regulations set out for food production equipment.

All other flue systems were installed continuously in Dinak DWJ twin wall throughout the height of the building to terminate above.

All chimney and flue products were supplied and installed CE Marked and compliant with European and regional standards.